We designed and manufactured the first Cracker in 1981 and set up a complete Crumbing/Reclamation plant in 1983.

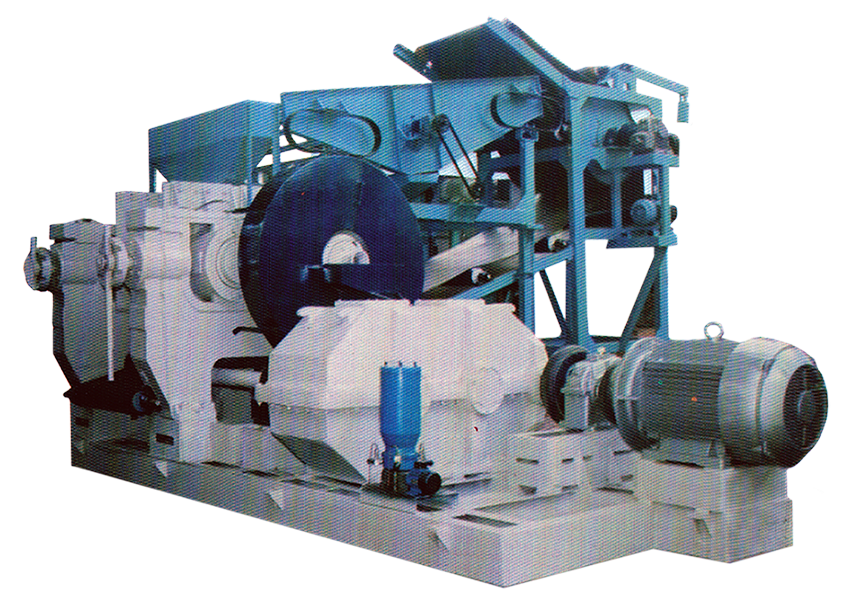

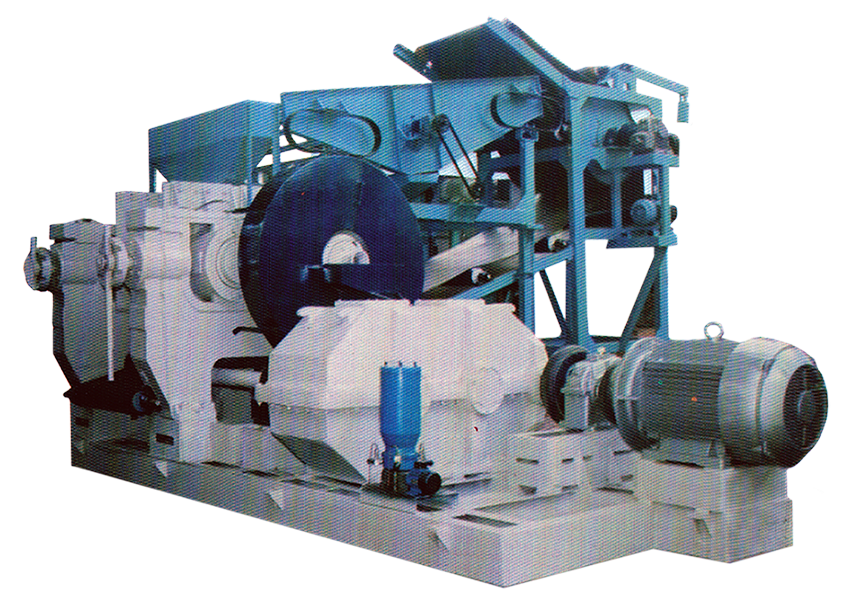

We have developed the most efficient, user-friendly, extra heavy-duty Crackers & Grinders mills of India in the DOUBLE BULL GEAR DRIVE Models.

-

Features of Rubber Cracker Mill

- Rigid Steel Casting Frame

- Graded Steel Casting Bull Gears

- Graded Steel Casting Gears and Pinion of reduction gear-boxes to with stand the heavy load.

- Well designed accurately machined fluting of rolls as per requirement.

- Re-teething, repeated turning or replacement of connecting gears is totally abolished with every regrooving/fluting of rolls.

- Reduction of roll wobblers size some times resulting in Cracking of rolls to accommodate smaller dia pinion is not required. In fact friction ratios as high as 3:1 are easily available.

- Rolls need not to be discarded as after certain reduction in diameter, friction gears no more remain compatible. Optimum utilization of the rolls (till the end of the chill depth) is possible, without making any changes in the transmission or otherwise with mills.

-

Range of Rubber Cracker Mill

12"x18", 14"x14"x18", 16"x16"x24", 18"x18"x30", 24"x24"x36", Size are available against order, with their respetive recirculation systems with vibratory sieves.

Accurated, high-speed, high frition, Rifiner Mills in sizes 15"x17"x24", 22"x18"x30", 21"x24"x36" are available with Phosphor Bronze bushes/Anti friction bearings.

Fifty Customers from all over India are satisfactory using the 'Anant' make crackers, Grinders, Refiners and Breakers comprising more than Two Hundred Machine units.

We also manufacture Cracker/Grinder/Pre-Refiner & Refiner mills in direct coupling gear type & Uni-Drive Models.